Sewer Cleaning and Inspection

Why is Cleaning and Inspection Necessary ?

The District's collection system includes approximately 17.38 miles (91,766 linear feet) of sewer collection pipeline, as well as 160 manholes and 3 pump stations. The pipeline ranges in size from 4 inches to 12 inches in diameter.

In addition to the District's Mission Statement to preserve and protect the environment for future generations, Order No. 2006-0003-DWQ, the Statewide General Waste Discharge Requirements for Sanitary Sewer Systems, further mandates proper management of wastewater collection systems to reduce the occurrences of sanitary sewer overflows (SSOs).

What does Sewer Cleaning Work entail?

The District maintains an enhanced system-wide cleaning program for the gravity sewers in its collection system necessary to reduce or prevent future SSOs.

The cleaning program includes preventative cleaning of problem gravity sewer segments (SSO "hot spots"), a system-wide proactive cleaning of all gravity sewers and a condition-based proactive cleaning of all gravity sewers with a cleaning cycle of approximately 5 years.

The District's cleaning efforts include both in-house and contract hydro jetting as well as line flushing. For larger diameter pipes and hard to get to sections of the collection system, the District utilizes contract vactor trucks and sewer easement carts as pictured here.

Hydro jetting is a sewer-cleaning process that utilizes a low volume of water (up to 18 gallons per minute) under high pressure (up to 4000 PSI). This is a standard industry approach designed to scour the walls of underground pipes removing potential obstructions (grease, roots) from the inner wall of the pipe and returning it back to its original diameter.

Cleaning activities are scheduled and the data is collected for analysis in the District's asset management (AMS) and geographic information (GIS) systems which are the primary storage locations for inspection data and defect coding on each pipe segment both spatially and over time.

The assessments are made consistent using the Pipeline Assessment Certification Program (PACP) rating system which has become standard practice in the industry. Condition assessment enhances the ability of the District to make technically sound judgments regarding management of these pipe segment assets. The GIS component manages the spatial information associated with the data and provides powerful visualization and analytical tools such as proximity of assets to critical or sensitive features such as water ways, residences and commercial facilities.

How about Sewer Inspection?

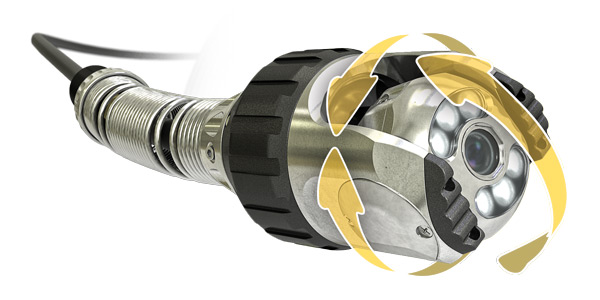

Once the collection line segments have been cleaned, a "sewer camera" is sent underground for live video inspection of each segment. Crews in real-time observe the the inside of the sewer pipes making digital notes via a small computer attached to the camera to assess and rate each segment's condition. This inspection data is then entered into the District's asset management system with a "score" based on condition which allows the District to schedule pipe maintenance, repairs and replacements as necessary.

pipe maintenance, repairs and replacements as necessary.

How long does it take?

Sewer cleaning and inspection work is performed in the summer months (June - October) when District staff can access the collection system. The District's objective is to clean and perform video analysis on approximately 1000 linear feet per week or 15,000 linear feet per summer to maintain the 5-year system-wide cycle.

Bear Valley's pipe segments range in length from 150 feet to as long as 600 feet. Cleaning and videoing each segment can take from a few hours to a few days.

Parking and traffic impacts will be minimal in the area, with appropriate controls and signage in place. To reduce impacts on the community, the District may clean several sewer lines on one block at a time.

Sewer service in the area will not be interrupted. Odors may increase temporarily, but will subside once work is completed.

Noise levels will be within reasonable limits.